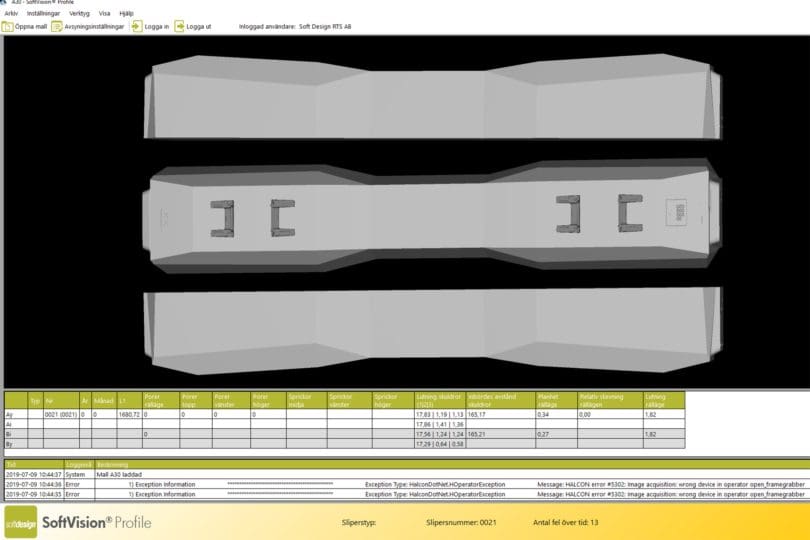

SoftVision Profile is a vision based system for quality control of manufactured products. The system finds defects, like cracks, holes or added material, that would have been difficult to find without 3D technology.

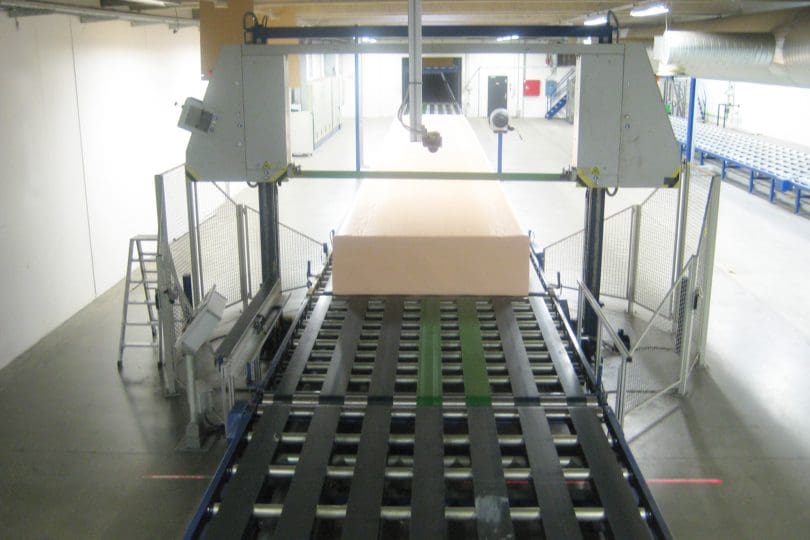

Settings for tolerance in height, width, corner radius and shape deviations like skew and twisting are set up in the system. SoftVision Profile operates with laser triangulation which is a very accurate and non mechanical method. Based on this the system can verify that the product has the correct shape and dimensions according to its specification.

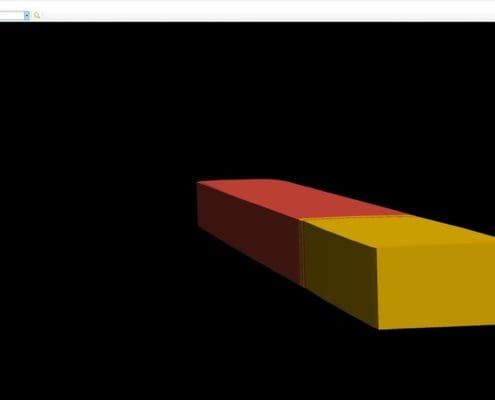

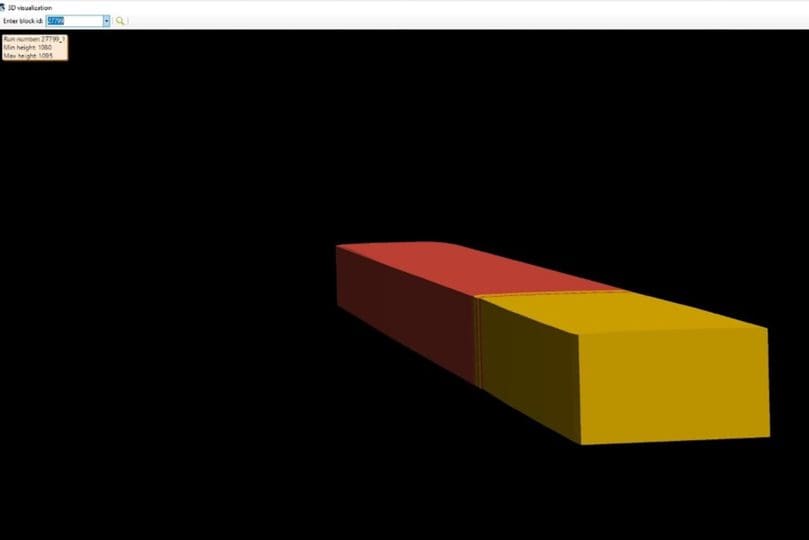

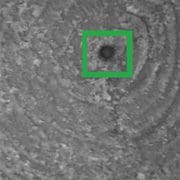

The SoftVision Profile system can be set up to provide an alarm to the operator if there is a faulty product. The system can also generate a 3D image of inspected products for reports or manual control of different areas.

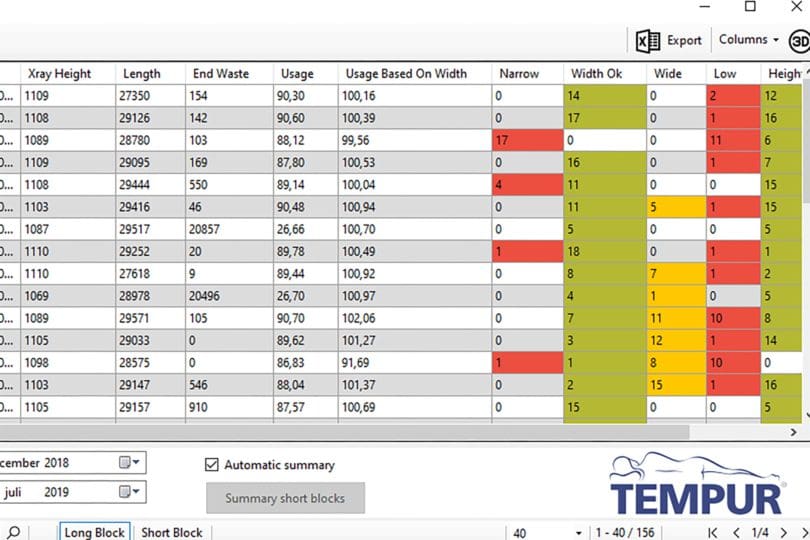

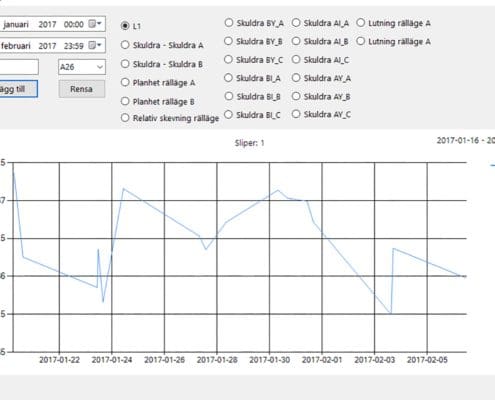

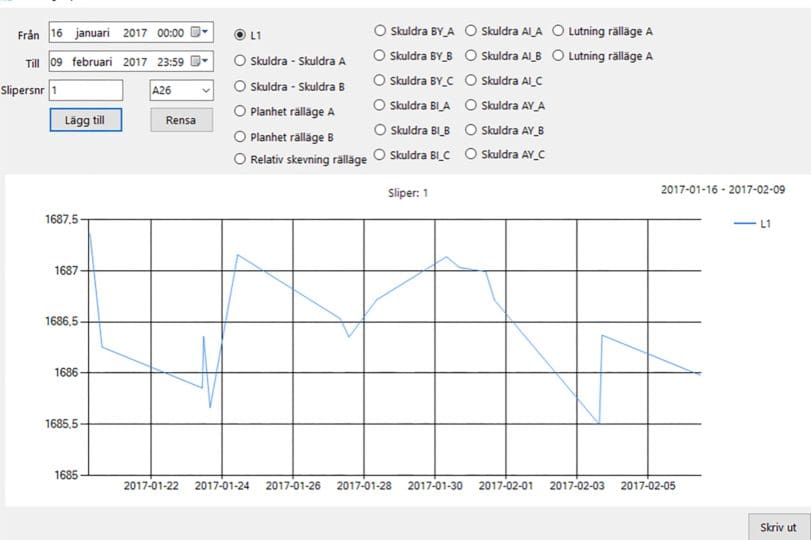

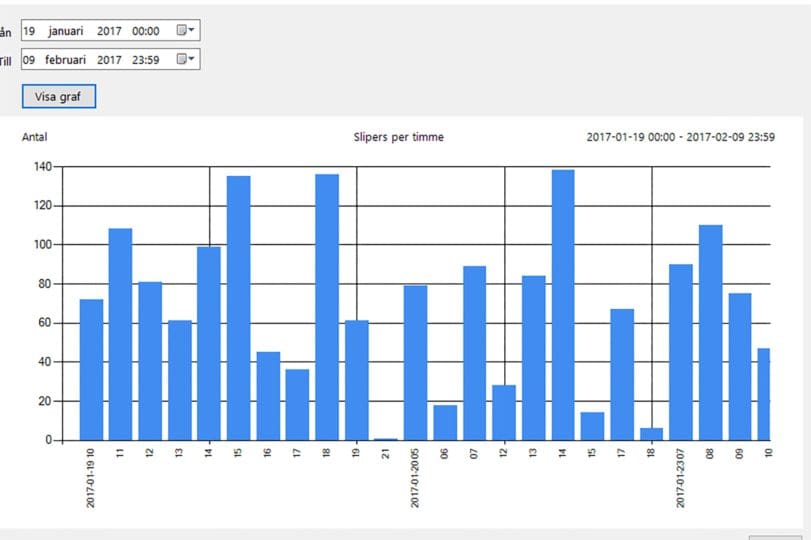

The system stores measured data and presents it in a customer adapted statistic application. Reports showing e.g. trends or deviations can be derived from the system.