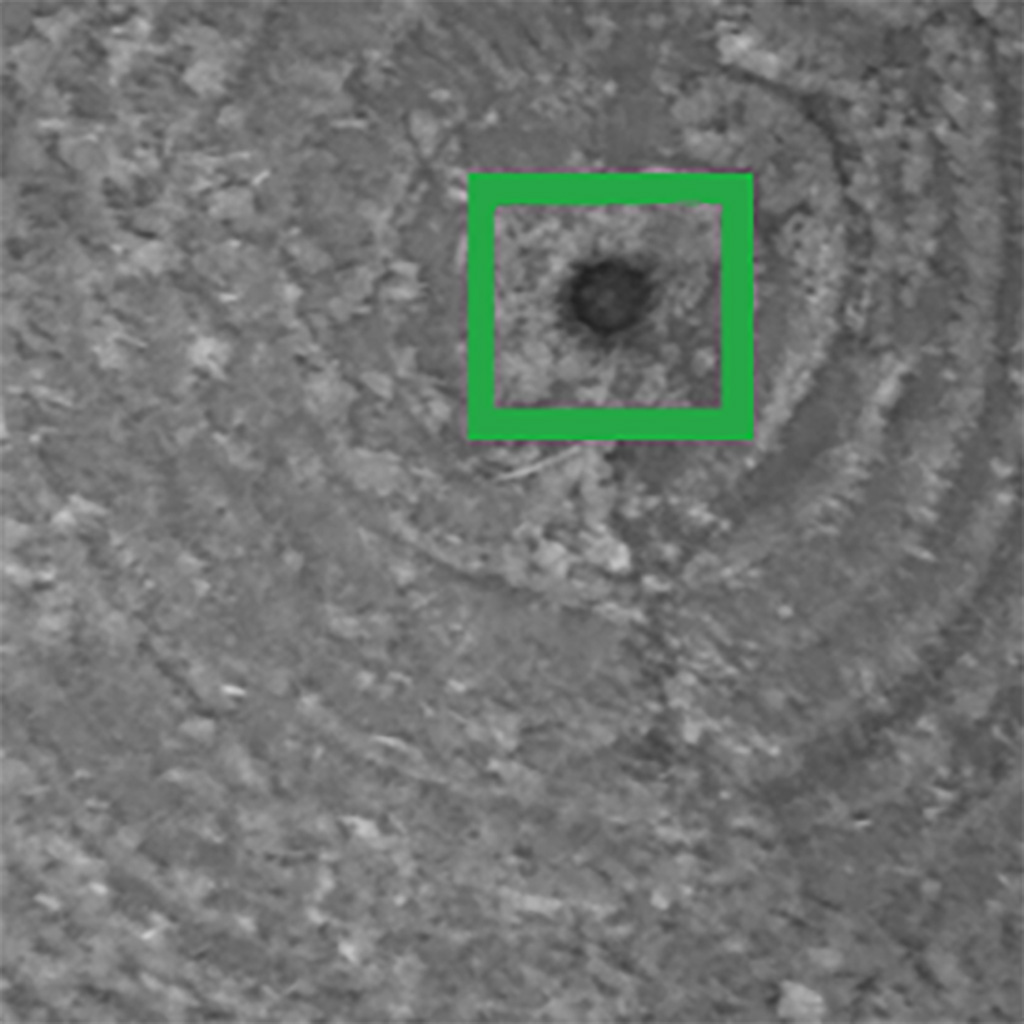

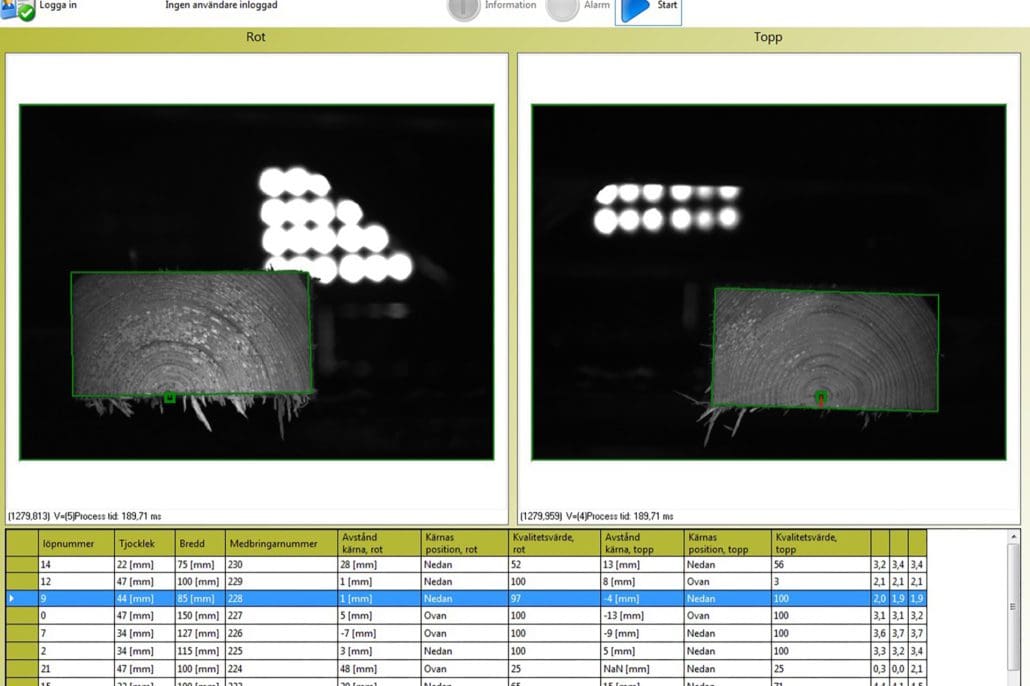

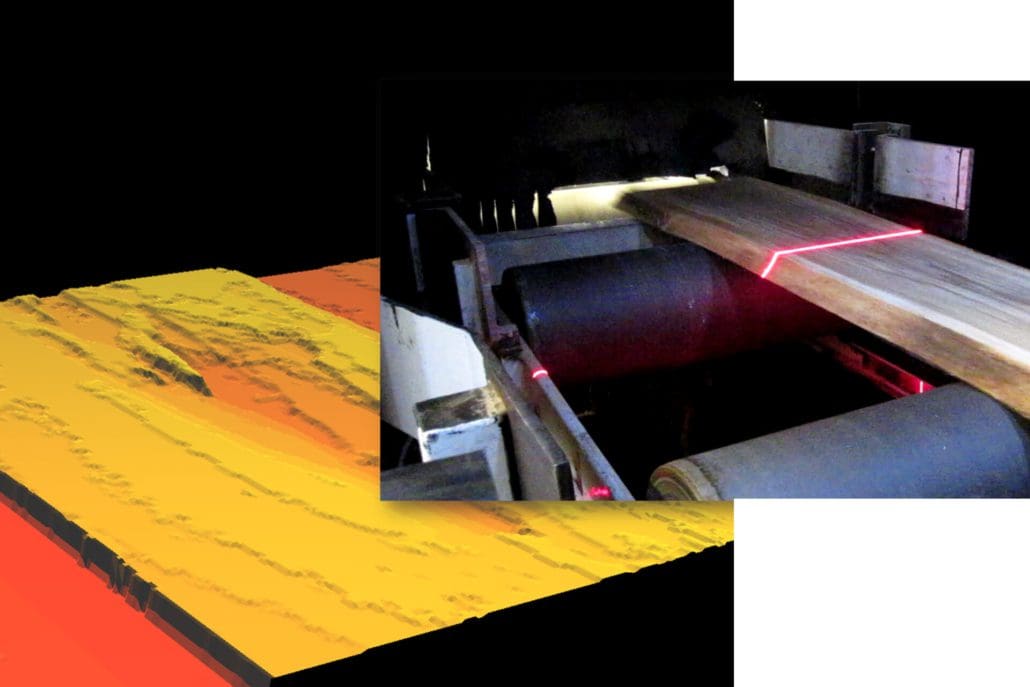

SoftVision Wood is an advanced vision based system specifically developed to support processes in the wood industry. The system optimizes cutting of parts such as logs and boards to maximize material usage. Defects such as wane, marrow, sapwood, decay, knots and cracks are detected by the system, combining color inspection and 3D measuring.

At inspection of a log, SoftVision Wood selects among a number of pre-defined formats and products with different properties. Based on these criteria, together with information on the measured shape and detected defects, SoftVision Wood calculates the most valuable combination of products for each wooden piece.

The optimization result transferred to the sawing equipment can be used for both lengthwise sawing and cutting, including sorting. Optimizing algorithms run parallel with measuring to maintain capacity. Different types of reports and statistics can be exported from the SoftVision Wood system. Examples include shift statistics, change lists, trendgraph analysis, measured and optimized volumes etc.