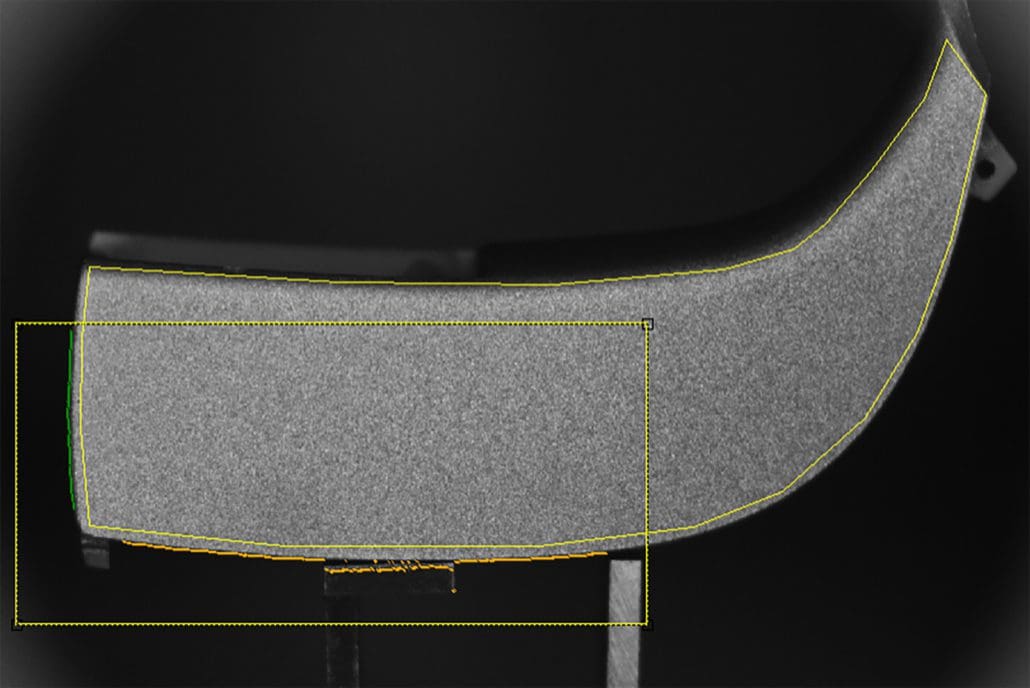

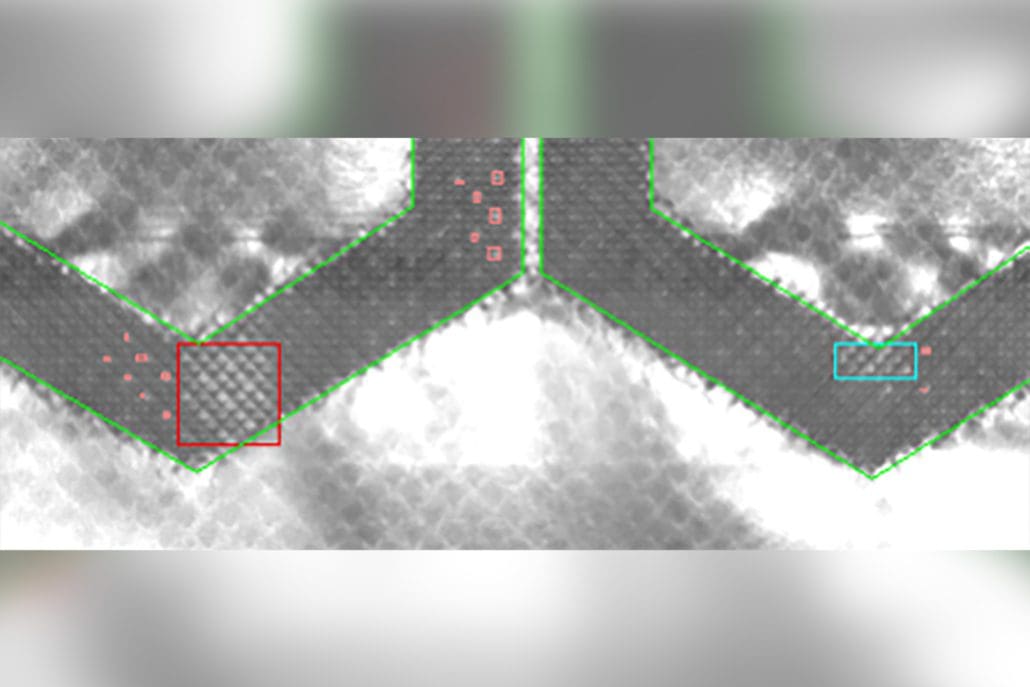

SoftVision Surface is used for product inspection to find different types of deviations in terms of pattern, structure, colour and finish. The system can find deviations less than 1/10 mm, which are very hard for the human eye to detect. Also, compared to the human eye, the vision system can work at a much higher speed and operate unlimited working days.

SoftVision Surface uses cameras and illumination, combined with filtering and image processing. The system makes an assessment of the contrast and colour to determine if there is a faulty product. Different types of cameras can be used depending on the application, ranging from the most simple area scan camera to high resolution cameras with optimised light.

Deviations are reported to the operator or a supervising system. SoftVision Surface can be set up so that the operator receives an alarm when the system detects a product that deviates from given tolerances. Reports with statistics and trends can be exported from the system.